Pengaruh Suhu Sintering Terhadap Morfologi Dan Bandgap Nanokomposit Fe3o4/Sio2/Tio2 Dengan Metode Kopresipitasi

DOI:

https://doi.org/10.23960/jtaf.v14i01.577Abstract

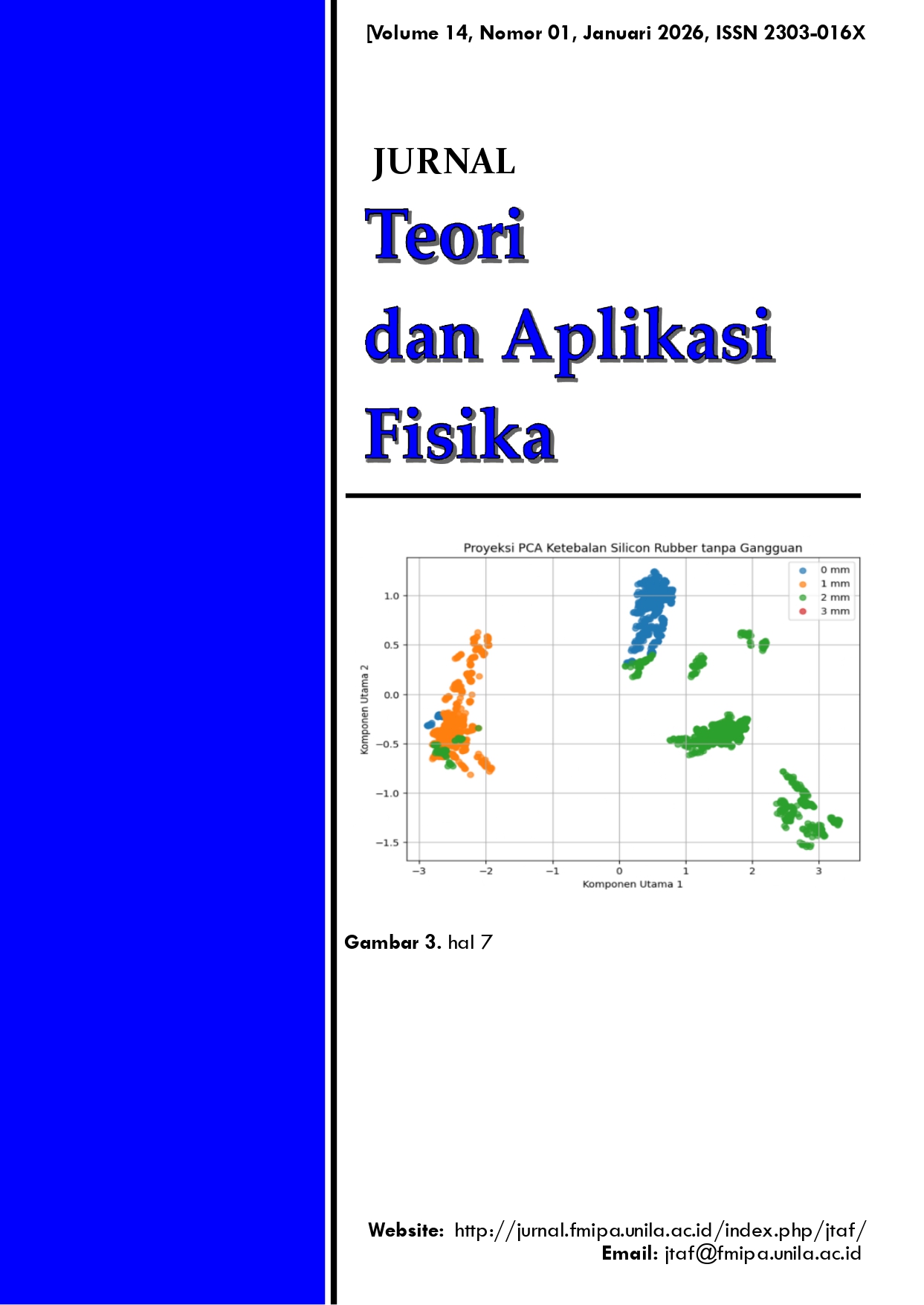

Fe₃O₄, TiO₂, and SiO₂ nanocomposite materials have been extensively investigated for their potential in various physical and environmental applications, particularly in the photocatalytic degradation of textile wastewater containing toxic organic dyes such as Methylene Blue. This study aims to determine the effect of sintering temperature on the morphology and bandgap energy of Fe₃O₄/TiO₂/SiO₂ nanocomposites synthesized using the coprecipitation method. The synthesized samples were subjected to sintering at temperatures of 500 °C, 550 °C, and 600 °C. Characterization was performed using Scanning Electron Microscopy (SEM) to observe morphological changes and Ultraviolet–Visible (UV–Vis) spectrophotometry to determine the bandgap energy. The SEM results revealed that higher sintering temperatures led to increased agglomeration and grain size, with the dominant particle size ranging between 0.22 µm and 0.24 µm. Furthermore, an increase in grain size correlated with a slight rise in bandgap energy from 2.35 eV to 2.37 eV, attributed to the widening separation between the valence and conduction bands. Among all samples, the FST500 nanocomposite (sintered at 500 °C) exhibited the most optimal properties, characterized by smaller agglomeration, finer grain size, and lower bandgap energy. These findings demonstrate that sintering temperature plays a crucial role in controlling the structural and optical properties of Fe₃O₄/TiO₂/SiO₂ nanocomposites for potential photocatalytic applications in wastewater treatment.

Keywords: Fe3O4/TiO2/SiO2, Coprecipitation, Sintering Temperature, Morphology, Bandgap Energy

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2026 Ridwan Yusuf Lubis, Ahya Zaelani, Miftahul Husnah, Ali Affan Silalahi

This work is licensed under a Creative Commons Attribution 4.0 International License.